WABCO PROJECTS

XY-ACTUATOR ASSEMBLY

XY Actuator station is designed to assemble the automatic gear cylinder piston which has 9 assembly stations handled by an electrical nut runner, servo motors, 2D scanners, pressing tools and a conveyor system. All 9 stations are connected to the server with the help of ethernet communication to handle the data volumes of the process.

DDSBA PERFORMANCE TEST RIG

This machine has been designed to check the performance of the test RIG which is completely simulated and operated by advance Labview programs. The main reason to select Labview programming method due to availability of its large volume of virtual instruments. It helps to simulate graphically with live instruments in case of testing sequence and can give high accuracy with reliable quality.

SERVO PRESS APPLICATION

Bush Pressing Station of gear cylinder actuator operated by vertical & horizontal servo action by validating load & position. Oil restrictor & ball pressing station for pneumatic vacuum pump. Involves servo based ball press with industrial vision checking and electrical nut runner is provided measure the torques.

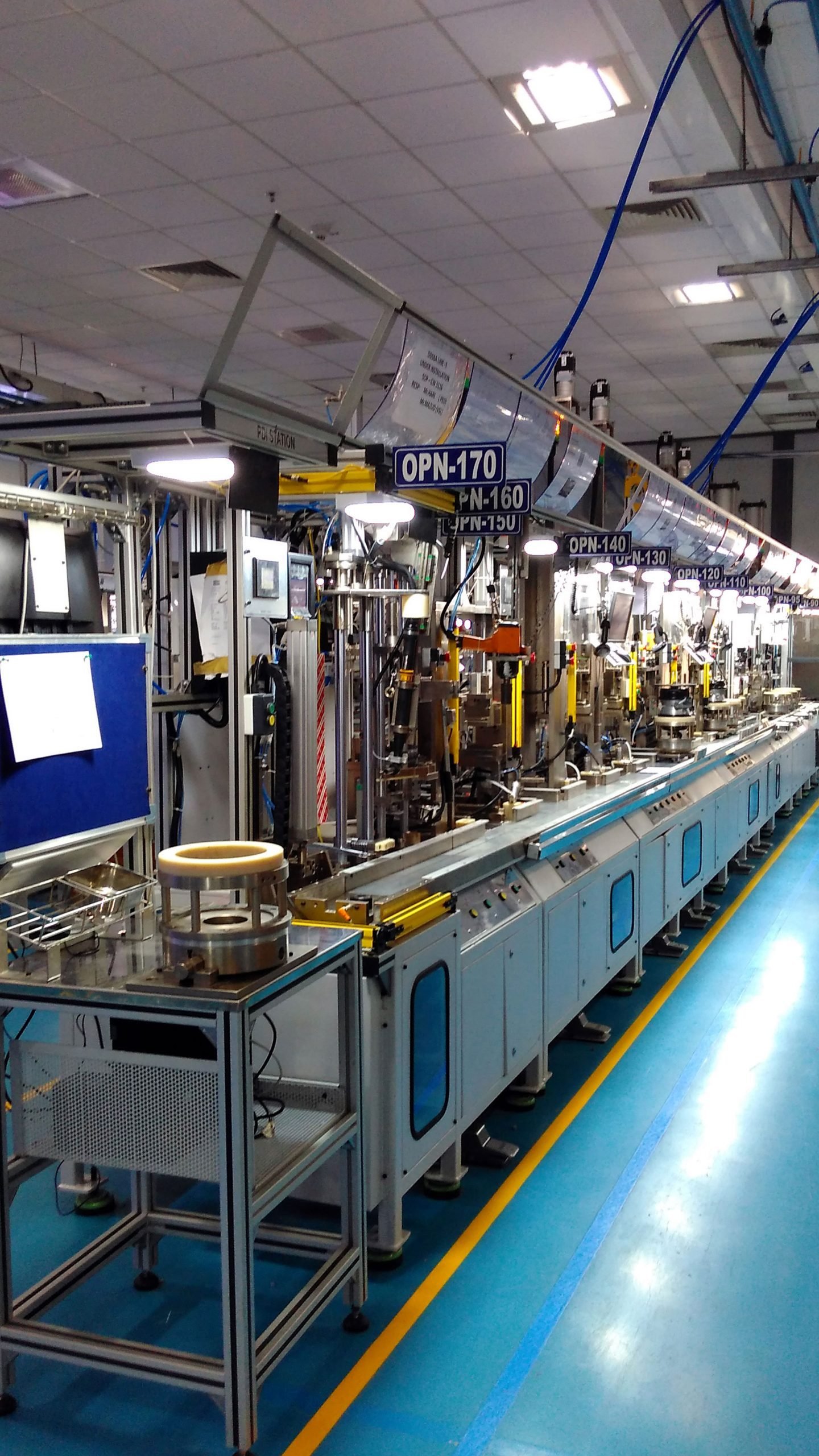

FULL AUTOMATIC ASSEMBLY STATION

Full automatic wheel speed sensor assembly with servo-based pick and place, components are poured to the vibrating bowl feeder, high-speed assembly with less than 7 seconds of cycle time for each component.

- Resistance measurement

- Angle measurement though vision camera

- Height measurement through pneumatic LVDT setup

- Automatic fault detection before & after assemble

- Automatic fault job pickup using servo

- Insulation testing after assemble

VOLVO-VACUUM PUMP PERFORMANCE TESTING

- Dual stage performance test rig to improve production rate

- Fully sound proof design

- RFID based operation control

- Scanner interface for 2D-matrix detection for complete traceability

- NI-Labview software tool is used to control the machine operations

WE ARE EXPERTS IN

- All type of Analog & Digital communication

- Performance & leak testing stations

- Servo based torque arm

- Full & semi automatic conveyor assembly line

- Research & development projects